CPES2021 Program

02 h 00 → 03 h 00 (Forward) in Quebec.

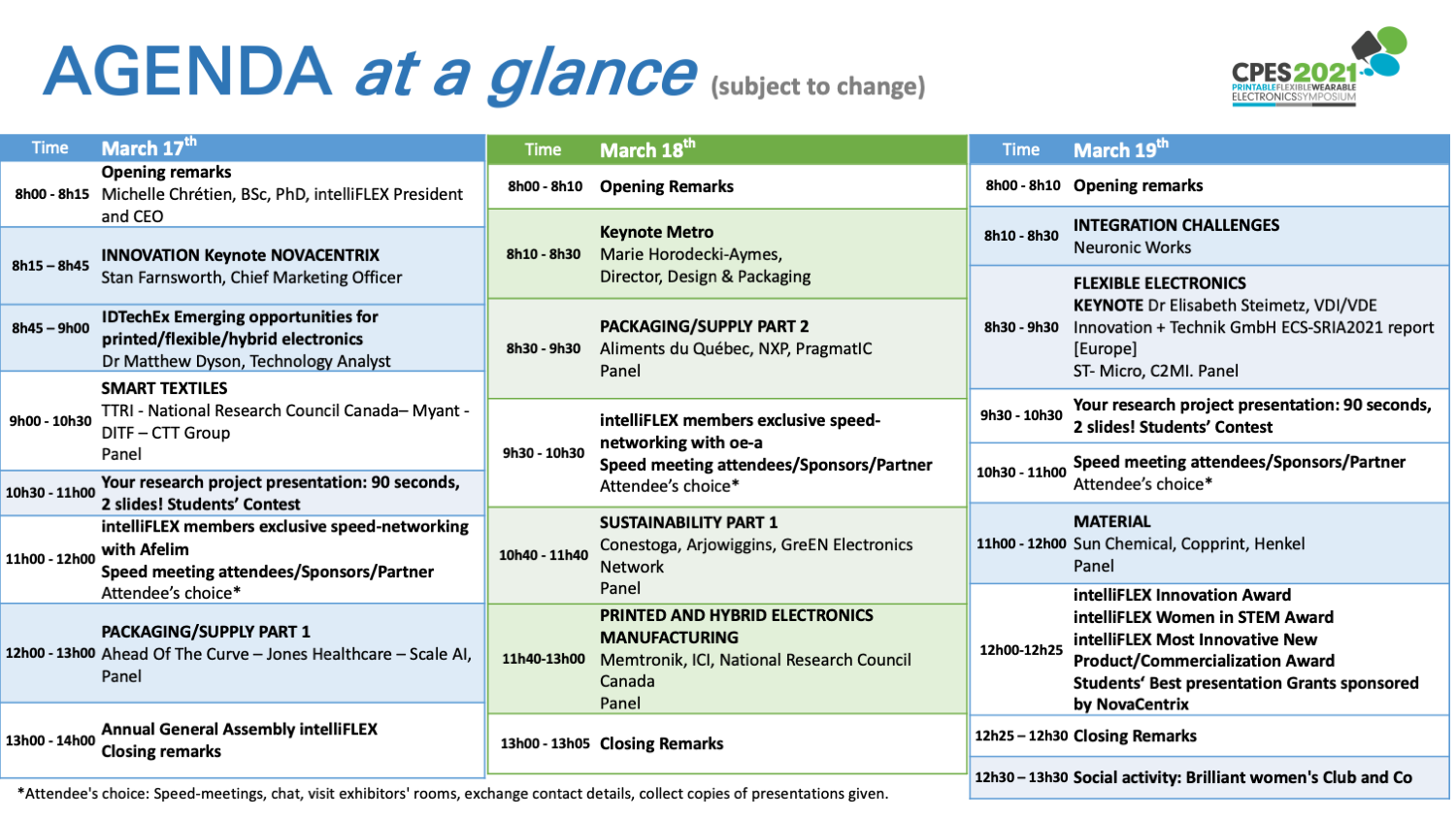

AGENDA DAY 1

March 17th

8h00-8h15

Opening remarks

Michelle Chrétien, BSc, PhD

8h15-8h45

Innovation

Stan Farnsworth, Chief Marketing Officer

In spite of the hardships and challenges during the past year, many innovators have also experienced a “compressed disruption”, driven by the acceleration of the digital revolution. Macro trends of 5G and AI plus the societal impact of the pandemic are driving e-commerce and IoT expansion. Simultaneously, consumer expectations for transportation and entertainment are evolving rapidly. Stan will share thoughts on how these global developments might in turn impact the development and adoption of printed/flexible hybrid electronics technologies.

8h45-9h00

Emerging opportunities for printed/flexible/hybrid electronics

Dr Matthew Dyson, Technology Analyst

Printed/flexible electronics has long been promoted as an enabling technology for low-cost, light-weight widespread integration of electronic functionality into everyday life, but to date has limited adoption outside displays, RFID tags, and some printed sensors. This relative lack of traction is largely due to the difficulty of competing with the capabilities of conventionally manufactured electronics.

However, the adoption of flexible hybrid electronics (FHE), in which printed and flexible circuits are combined with mounted components such as integrated circuits, promises the best of both worlds. FHE is highly applicable to applications such as electronic skin patches that facilitate continuous healthcare/fitness monitoring, and to the potentially very large market of smart packaging. Furthermore, printed electronics is enabling new manufacturing methodologies such as in-mold electronics (IME) and printing circuits directly onto 3D surfaces, both of which promise simpler and cheaper manufacturing with fewer materials. The talk will review the status and future opportunities within these and other applications, along with technical and commercial challenges.

9h-10h30

SMART TEXTILES

Chair Marie O’Mahony

Visiting Professor, RCA, London

9h00-9h15

Current Situation of Smart textile Industries in Taiwan

Dr S. F. Chiu, representing TTRI (Taiwan Textile Research Institute) and TSTA (Taiwan Smart Textiles Association)

Smart textiles has been developed in Taiwan for more than 20 years. TTRI is one of major R&D institutes where conductive material, sensor component, fabric module and controlled system are designed and developed. There are different types of smart textiles developed and used for special end-uses including lighting (LED fabric), heating (heated fabric), sensing(detect vital signs) and motoring(electric stimulation) sensors and modules.

In textile industries, many companies, specially for garment manufacturers such as Texray, Formosa Taffeta, Eclat, Far East, Makalot, Rimtai and Everest, are intended to looking for any opportunities to create an innovative technology of making smart textiles or clothes. AiQ was a start-up company from Texray group since 2010, which produce functional fabrics and garments world wide, and developed smart fabric modules as a solution provider but still keep going by painstaking effort.

TTRI played a very important role on helping the industry to transfer into a more high-value added industry with smart textiles and also organizing a Taiwan Smart Textile Association (tsta), which integrated electronic and textile industries together and expect to accelerate the commercialization pace of change

9h15-9h30

Conductive Materials and Process for Textiles

Dr Frank Zhang, Principal Research Officer

Conductive Materials and Process for Textiles

Zhiyi Zhang, Gaozhi Xiao, Ta-ya Chu, and Ye Tao

Advanced Electronic and Photonic Research Center, National Research Council Canada, Ottawa, Ontario

We have developed various conductive materials and processes for fabricating conductive circuits on textiles and in textiles. For the circuits on textiles, the products fabricated with our stretchable conductive materials and processes have been tested to meet the industrial standards. For the circuits in textiles, our reactive silver inks can penetrate into textiles and coat each individual fiber of the involved yarns within minutes at room temperature. The reactive silver inks can be also used to produce conductive yarns, rapidly at low cost, using commercial yarns and even sewing machine threads. In addition, we have developed highly conductive Kevlar yarns for high-performance and military applications.

9H30-9H45

Integration and Connection : The challenges of textile computing in 2021

Andrea Ferrone, Ph.D. MEng , Electronic Engineers in applied electronics for Industry and Innovation

Nowadays, wearable devices have a growing impact on our lifestyle.

The experts project that textile computing (or E-Textile) is going to be the next generation of smart wearables.

One of the main challenges that need to be faced is a stable automated manufacturing process for embedding electronics components.

For the time being, most of the processes required a large number of manual production steps that cause high prices, which slow down market growth.

For this reason, at Myant, we are developing and analyzing different techniques and methodologies of contacting process for electronics parts on e-textile.

The processes investigated have a great potential to be automated and industrialized in the next generation of knitting textile computing.

At Myant, we have the mission of transforming human connectedness by creating the world’s first platform in textile computing, which continuously and ambiently connects people to their own bodies, to each other, and the world.

9H45-10H00

New European Directions in R+D+I :

from sustainability to international collaboration

Dr Thomas Stegmaier, Prof. Dr. Götz Gresser

A range of new European policies have been launched that will impact significantly on the future of R+D+I across all sectors including textiles and electronics.

This presentation begins by looking at the overarching policy theme of sustainability that directly impacts four of the five mission areas identified by the newly launched Horizon Europe (successor to Horizon 2020). We will present our view of its potential impact on smart materials and applications such as wearable technology.

The second portion of this presentation will focus on the integration of FHE into and onto fibers and fabrics, showcasing current and recent projects that we have worked on. At DITF we have extensive experience working with SMEs as well as other research institutions so that we see these policies as offering further opportunity for innovation through cooperation within the European region and globally, to mutual benefit.

10h00-10h15

Contactless Bio-Monitoring for Transportation

Dominic Lachapelle, Eng.Electronic Engineers Project Leader

Despite being usually associated with clothes and garments, Smart Textiles technologies are also finding relevant applications in other sectors such as the transportation industry, which is considered cutting-edge with the development of autonomous and connected cars.

Long-distance travels are a known source of discomfort, stress and tiredness, which can affect the reflexes of the drivers in public transport system, for instance. For safety and insurance purposes, many companies require their drivers to receive a quick check-up before letting them on board. However, the check-up does not cover actual clinical measurement of bio-physical parameter of the person and is performed punctually without taking into account the impact of the travel.

The capacity to monitor in real-time the heart-rate and respiration rate of drivers and therefore identify signs of onset drowsiness and fatigue are extremely relevant for the transportation industry. It also represents some important technical challenges since all sensors must be contactless to allow for the person to wear clothes and be functional despite the absence of direct contact with the skin.

Overcoming these challenges, CTT Group has developed in partnership with Thales System Inc. contactless bio-sensors, embedded into a seat cover.

Use of conductive fabrics combined with tailored-yarn placement technique allowed a measurement which traced back to heart rate signal. On the other side, the respirate rate was determined using an assembly of thin pressure sensors applied against the back of the seat.

Such technology will be more and more integrated into the new cars structure and become common for the next generation of connected vehicles.

10h15-10h30

Panel

10h30-11h00

Your research project presentation :

90 seconds, 2 slides! Students’ Contest

Chair : Neil Graddage, Research Officer, NRC-CNRC

Jury members :

- Harry Chou, Application Engineer at NovaCentrix

- Laurette Vieille-Grosjean, Assistant General Director and Director of the Consultation and Industrial Research Service at ICI

- Martin Bolduc, Professor and Research Chair on Intelligent Manufacturing at Université du Québec à Trois-Rivières

- Yuning Li, Ph.D., P. Eng., Professor, Department of Chemical Engineering and Waterloo Institute for Nanotechnology (WIN), University of Waterloo, GreEN Network

11h00-12h00

intelliFLEX members exclusive speed-networking with Afelim

Anne-Lise Marechal, Delegué Géneral, AFELIM

Mickael Rougette, Neuronic Works

SPEED MEETING

12h00-13h00

PACKAGING / SUPPLY PART 1

Chair: Christina Cvetan

Co-Founder and Partner, A Head Of The Curve

12h00-12h15

TapScan…The New Frontier for Engaging Shoppers in a Touch-Free World

Terry Dennis , Consumer Products Executive with International expertise in Corporate Strategy, Marketing, Sales and Operations.

Brands & retailers are speechless looking for a new frontier to engage shoppers & consumers in a meaningful way.

Despite the recent environment and retail restrictions global brands have connected TapScan to enhance the shopping experience.

12h15-12h30

Manufacturing Smart Packaging … Why ?

James Lee, Director, Innovation Solutions Group

In this talk James will discuss reasons why integrating directly into packaging benefits the supply chain. He will describe what is currently possible in the packaging manufacturing chain and what is needed to enable further integration in the future.

12h30-12h45

AI in innovative supply chains

Clément Bourgogne, Chief Operating Officer

Overview of AI applications and concrete AI project examples in supply chain, distribution and packaging.

12h45-13h00

Panel

13h00-14h00

Closing remarks

Annual General Assembly intelliFlex

AGENDA DAY 2

March 18th

8h00-8h10

Opening Remarks

Michelle Chrétien, BSc, PhD, intelliFLEX President and CEO and Associate Vice President, Research at Conestoga College.

Howard W. Campbell, Chair of the intelliFLEX Board of Directors.

8h10-8h30

Packaging : Doing the right thing may be tricky

Marie HORODECKI-AYMES, Director, Design & Packaging

The Covid-19 pandemic has emphasized the importance of packaging for food safety, and protection. In order to protect and ensure the quality of the products we offer, packaging plays a key role. However, once the product is consumed, the packaging becomes waste.

Each decision we take, each enhancement we make have to be measured against the packaging end of life : waste or material

8h30-9h30

8h30-8h45

PACKAGING / SUPPLY PART 2

Chair : Chloé Bois, General Director at ICI and NSERC Industrial Research Chair for Colleges in Functional Printed Applications Manufacturing

Food industry challenges over and above the pandemic period

Marie Beaudry, Directrice Générale

This conference will present the main challenges the food industry companies have to overcome during and after the pandemic period in order to meet the new market trends and survive in a continually more complex environment.

8h45-9h00

Smart Packaging and Healthcare – How hybrid electronics are changing the healthcare industrie

Stefan De Troch, Director of Business Development of NXP’s NTAG® SmartSensor portfolio

As the first vaccines against Covid-19 become available, the question of proper storage and delivery arises. Since many vaccines are temperature sensitive, electronics are an essential part of the supply and distribution chain. While conventional electronics have been the standard cold chain solution, hybrid electronics are gaining traction as they combine the strengths of both technologies. In this talk, you will get a glimpse of how hybrid electronics are reshaping the healthcare industry, including NXP´s NTAG® SmartSensor solution family and its latest application cases in the field of healthcare and pharmaceutical.

9h00-9h15

PragmatIC’s high volume/low cost Flexible Electronics, Applications and Roadmap

Joao de Oliveira, SVP Business Development

Introduction to PragmatIC’s core technology, with high performance and low cost TFTs.

From design to high volume production with FlexLogIC Manufacturing platform, at a fraction of the cost and size of a traditional manufacturing plant. From RFID to generic applications, and multiple segments.

9h15-9h30

Panel

9h30 – 10h30

intelliFLEX members exclusive speed-networking with oe-a

Klaus Hecker, Managing Director at VDMA Organic and Printed Electronics Association (oe-a)

Stan Farnsworth, Chief Marketing Officer, NovaCentrix

SPEED MEETING

10h40-11h40

SUSTAINABILITY PART 1

Chair : Gregory C. Welch, PhD, Associate Professor, Chemistry

University of Calgary

10h40-10h55

Advanced Recycling Technologies for WEEE

Hamid Karbasi, PhD, P. Eng.

In this presentation, Dr. Karbasi will review the pandemic’s impacts on the production of e-waste and ITAD business of recycling companies, the benefits of urban mining, critical materials recovery, environment, and a Circular Economy. In the end, he will give an overview of his research at Conestoga College to develop advanced recycling technologies and build a unique WEEE lab and e-waste recycling pilot plant.

10h55-11h10

Recyclability of paper electronics

Gaël DEPRES, Central R&D Manager

Smart packaging and smart labels represent a huge potential market nowadays, and with the willingness to minimize the impact on environment and to target a circular economy, I will explain why printed electronics on paper is a good alternative versus other approaches.

In this talk, I will present our printing process line to manufacture smart labels and smart packaging and review the different objects we can print in production (NFC and UHF antenna, open detection, temperature sensors… ) as well as R&D programs. The recyclability will be analyzed on 2 real examples for a shock detection tags and an anticounterfeiting label on paper.

11h10-11h25

The NSERC Green Electronics Network

Chloé Bois, General Manager at the Printability and Graphic Communications Institute (ICI), and NSERC Industrial Research Chair for Colleges in Functional Printed Applications Manufacturing at Collège Ahuntsic, Montreal, QC, Canada.

Our world is rapidly adopting an information system known as the Internet of Things (IoT), in which smart devices and sensors embedded ubiquitously collect and exchange data. The IoT is estimated to consist of ~50B smart objects by 2020. Many of these devices will be simple, low-cost sensors deployed everywhere, monitoring food supplies, environmental conditions of air and water, the status of packaged goods, and human health. The resulting data will be used to improve human health and safety, as well as provide commercial benefits by preventing product loss. To make this vision a reality, the field of printable electronics (PE) is rapidly developing due to intense research efforts both in Canada and worldwide. PE combines conventional printing methods (gravure, flexography, screen printing, roll-to-roll) with conducting, dielectric, and semiconducting inks to economically produce electronic devices in a high throughput fashion. This unique synergy at the intersection between the printing and the electronics industries allows for the manufacturing of low-cost electronic devices that are light and flexible. The high throughput and low-cost manufacturing capabilities of PE are ideally suited to the mass production of devices needed for the IoT; however, the potential scale of this mass production also presents an environmental challenge that must be addressed for PE manufacturing to be a viable approach. There is an urgent need to reinvent the current methods of PE to incorporate green materials and processes to minimize the environmental impact.

In 2018, the NSERC Green Electronics Network was formed, consisting of world-class researchers in chemistry, physics, and engineering, from across Canada with a vision to address these key issues by exploiting the internationally recognized strengths of Canada in materials science and organic electronics to fabricate environmentally-friendly printed electronic sensors intended for smart packaging applications. This presentation will include a discussion of the vision and goals of this unprecedented network of researchers, along with recent advances from the network in the preparation and characterization of environmentally benign carbon-based conductors, dielectrics, and semiconductors using sustainable processes, their formulation into inks using environmentally-friendly solvents, and the printing and fabrication of electronic devices and circuits on various biodegradable or recyclable substrates.

11h25-11h40

Panel

11h40-13h00

PRINTED AND HYBRID ELECTRONICS MANUFACTURING

Chair : Matthew Dyson, Technology Analyst, IDTechEx

11h40-11h55

Evolving Requirements in Printed Electronics.

Howard W. Campbell, Business Development, Memtronik Innovations

The presentation focuses on the rapidly changing demands placed on Printed Electronics organizations. With the impetus of the demands of the medical community, the presentation examines the need for joint developments, greater precision and consistency, higher ramp-rates, high-volume through-put and increasing challenges related to service. It will also discuss choices and solutions.

11h55-12h10

Molecular Inks for In-Mold Electronics

Arnold Kell, Research Officer

A suite of silver molecular ink (MINK) platforms co-developed by researchers at the National Research Council of Canada and e2ip technologies is presented. MINK is particle-free and capable of producing thin, narrow, screen-printed traces with exceptional electrical and mechanical properties including bending, flexing and elongation. This talk discuss how these property enhancements have driven evolutionary changes in design and manufacturing of In-Mold Electronic (IME) devices at e2ip technologies and NRC.

12h10-12h25

Industrial research during pandemic : From adversity to opportunity

Ngoc-Duc Trinh, Project and Educational Transfer Manager

During this unique situation, the industrial research faces new challenges, and requires innovation in the way of working, with more creativity and flexibility to maintain safety, efficiency, and communication between peers. In this presentation, you will witness on how the ICI’s ecosystem evolves during pandemic and uses this opportunity to accentuate the effort concerning the industrialization of smart labels devoted to the traceability in the supply cold chain. Moreover, thanks to a multidisciplinary team, the fabrication of antimicrobial printed surfaces will be presented to help the packaging industry to face the current pandemic.

12h25-12h40

Panel

13h00-13h05

Closing Remarks

AGENDA DAY 3

March 19th

8h00-8h10

Opening Remarks

Michelle Chrétien, BSc, PhD, intelliFLEX President and CEO and Associate Vice President, Research at Conestoga College.

Howard W. Campbell, Chair of the intelliFLEX Board of Directors.

8h10-8h30

INTEGRATION CHALLENGES

Flexible PCBs, Design and Manufacturing Challenges

Michael Sugarman, Hardware Engineer

PCB Design process is both an art and a science. While rigid PCBs have been in production for several decades, flexible PCBs are still a market novelty. Given its flexible nature, flexible PCBs allow for considerable space reduction, increased product reliability, and reduced weight compared to classic rigid PCBs. Due to current technological limitations, however, flexible PCBs bring some interesting challenges to the table. This presentation will highlight a few of these challenges and how to best deal with them.

8h30-9h30

FLEXIBLE ELECTRONICS

Chair : Erika Rebrosova, Global Technology Manager – Electronic Materials, SunChemical

8h30-8h45

ECS-SRIA 2021 – an overview

Dr Elisabeth Steimetz,

Group Leader Intelligent Systems, Mobility and Infrastructure (SMI) at VDI / VDE Innovation + Technik GmbH

In this presentation Dr Elisabeth Steimetz presents some of the key findings of this year’s ECS-SRIA report reflecting the challenges and opportunities facing the electronic components and systems industry – including FHE. The annual report is developed by members of three European electronics industry associations: AENEAS, ARTEMIS and EPoSS. AENEAS represents the micro and nanoelectronics community, ARTEMIS embedded systems technologies and EPoSS the European Technology Platform on Smart Systems Integration.

8h45-9h00

Exploring MEMs and Sensors

Thiago Reis / MEMS & Sensors Product Marketing

ST offers the widest range of MEMS (Micro-Electro-Mechanical Systems) and sensors covering a full spectrum of applications from low-power devices for IoT and battery-operated applications to high-end devices for accurate navigation and positioning, Industry 4.0, augmented virtual reality components and smartphones. For Industry 4.0, ST provides a complete range of products suitable to be applied in early failure detection and predictive maintenance systems where vibration, temperature, pressure, sound and acoustics analysis are needed. The benefit of our 10 years longevity program is also available for Automotive and Industrial-grade devices as well for fitness and medical applications.

This 15 minute presentation will introduce a wide range of sensor technologies and provide a quick overview of the key applications that can be explored by our customers and partners.

9h00-9h15

Open innovation is closer than you think!

Marie-Josée Turgeon, P. Eng., MBA, Vice-President of Operations and Deputy General Manager

Whether it is in health sciences to develop new vaccine or in microelectronics to develop next generation optical switch, open innovation pushes a faster development pace and a shorter time to market. The winning ingredients for successful open innovation are all in place within C2MI : an ecosystem of more than 350 SMEs and large companies sharing their expertise and know-how, research support and highly qualified personnel from many universities, more than 50 000 ft2 of cleanrooms, state-of-the-art equipment offering a complete service offering from MEMS, advanced packaging, printed electronics, reliability tests to card assembly and most recently a live showcase for Smart Manufacturing solutions, flexible IP model and government contribution through different innovation programs. Whatever the idea, we will develop it together !

9h15-9h30

Panel

9h30-10h30

Your research project presentation :

90 seconds, 2 slides! Students’ Contest

Chair : Neil Graddage, Research Officer, NRC-CNRC

Jury members:

- Harry Chou, Application Engineer at NovaCentrix

- Laurette Vieille-Grosjean, Assistant General Director and Director of the Consultation and Industrial Research Service at ICI

- Martin Bolduc, Professor and Research Chair on Intelligent Manufacturing at Université du Québec à Trois-Rivières

- Yuning Li, Ph.D., P. Eng., Professor, Department of Chemical Engineering and Waterloo Institute for Nanotechnology (WIN), University of Waterloo, GreEN Network

10h30-11h00

SPEED MEETING

11h00-12h00

MATERIAL

Chair : Martin Bolduc, Professor and Research Chair on Intelligent Manufacturing

at Université du Québec à Trois-Rivières

11h00-11h15

High Resolution Screen Printing for Flexible Hybrid Electronics Applications

Erika Rebrosova, Global Technology Manager – Electronic Materials

Recently, high resolution functional printing gained a lot of attention, mainly due to the promise of enabling new applications which will expand the competitiveness of printed electronics. The presentation will review the main trends and drivers for fine line functional printing and discuss emerging application that can benefit from high resolution printability of electronic materials. It will also provide an insight into the world of paste development and properties critical for high resolution functional printing.

11h15-11h30

Copper pastes that outperform silver – make the switch: Higher conductivity, lower cost, and superior sustainability

Dr Ofer Shochet, Co-Founder & CEO, Copprint

In this presentation, we will review Copper pastes, which are superior to silver pastes and to etching techniques. These pastes are suitable for various substrates such as Paper, PET, PI, Glass, Aluminum, Alumina, FR4, silicon wafers and photovoltaic wafers. We will review different applications such as printed antennas, heaters, flexible circuits, PCBs, and displays. We will demonstrate that a very high level of conductivity can be obtained with Copprint’s Nano-Copper pastes while dramatically reducing costs and using simple low-cost equipment and under-air processing. All our Copper inks are commercially available for purchase.

11h30-11h45

Material Advancements for Smart Healthcare, Hygiene & Consumer Surface Applications

Dr Carla Negele

Head of Product Development Printed Electronics

Henkel AG & Co. KGaA

Functional adhesives and printed electronics solutions are offered by Henkel to enable production of smart sensors in an economically attractive way. These sensors can be easily integrated into existing products applications for healthcare, hygiene and consumer surfaces.